- #HYPERMILL REVIEW MANUAL#

- #HYPERMILL REVIEW SOFTWARE#

- #HYPERMILL REVIEW CODE#

- #HYPERMILL REVIEW PLUS#

The 35,000 ft² (3,251.6 m²) shop, founded in 1972, is run by Heriberto López, staffed by 36 employees. Extensive tool manufacturing is also driven by this growth, including moldmaking, and Molrio, a Guadalajara machine shop focused primarily on the manufacture and repair of tire molds, has benefited. Mexico’s tire market has been growing substantially, fueled by an aggressive increase in automotive industry manufacturing across the country.

#HYPERMILL REVIEW SOFTWARE#

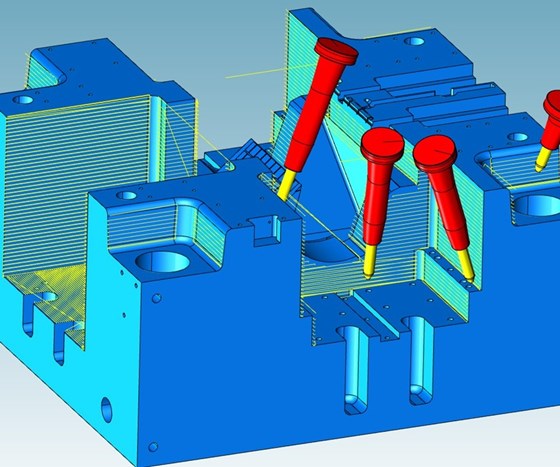

hyperMILL provides innovative strategies such as 2.5D, 3D as well as 5-axis milling/mill turning, and machining operations like HSC and HPC.With hyperMILL CAM software from Open Mind Technologies, CNC machining operations at Molrio, a Guadalajara machine shop, have been operating at peak performance. The company develops optimized CAM solutions that include a high number of innovative features not available elsewhere. OPEN MIND is one of the world’s most sought-after developers of powerful CAM solutions for machine and controller-independent programming. What makes this unique is that unlike previous solutions available on the market, hyperMILL BEST FIT does not change the origin on the controller and generates completely collision-checked toolpaths.” This could include reworking refurbished parts and imperfect forged parts, machining parts that are too heavy to be aligned by hand, eliminating the need for high-precision equipment, and more. “Component alignment at the touch of a button is a real game changer in many application areas. hyperMILL detects the situation on the machine and aligns the component virtually,” explains Manfred Guggemos, Product Manager at OPEN MIND Technologies.

“Thanks to hyperMILL BEST FIT, time-consuming and unsafe component alignment on the machine is a thing of the past.

#HYPERMILL REVIEW CODE#

The virtual world (programming) is adapted to the real world (clamping), not the other way around! The adjusted NC code is then simulated in the virtual machine on the actual clamping setup, and automatically optimized.Ī real game changer in many application areas The unaligned stock is probed on the machine by way of a 3D measurement, the measurement log is sent to the CAM system, and hyperMILL BEST FIT adjusts the NC code to the actual position of the component. One way to solve this issue is to align the component in CAM in real time. This process was time-intensive, often needed to be repeated multiple times, and involved a number of uncertainties. The actual clamping operation is adapted to conform to the virtual programming.

#HYPERMILL REVIEW PLUS#

The component is aligned manually, using a dial gauge, control cycles, plus a great deal of sensitivity. Up to now, it has been standard practice to adapt the stock and the clamping in the machine to the conditions of the NC program. Real-time alignment for reliable, plannable processes

#HYPERMILL REVIEW MANUAL#

HyperMILL BEST FIT takes full advantage of the options offered by the virtual machine in the CAM program and communication with a 5-axis machining center capable of 3D measurements to eliminate the uncertainty that comes with manual alignment.

Each of these processes requires a delicate touch to calibrate it with the CAD model of the end product. This method saves time and increases process reliability, especially with cast, forged, welded, and additively manufactured stocks with small or irregular allowances, when reworking heat-treated parts, and during machine changeovers. Instead of having to align the unmachined part in the clamping to the NC program manually, the hyperMILL CAM system aligns the NC program automatically to the component position. WESSLING, Germany, – OPEN MIND’s hyperMILL BEST FIT is a new function that is revolutionizing planning in machining operations.

0 kommentar(er)

0 kommentar(er)